MecTitan

Following the success of our vacuum dryer, we decided to propose to the market a complementary product: The MecTitan staking machine.

This machine is commonly used immediately after drying to soften the skin fibers, which are usually compressed and stiffened by the action of heat and vacuum.

Technical table

| Model | 1800 | 2000 | 2400 | 3200 | 3400 |

|---|---|---|---|---|---|

| Lenght | 2420 | 2620 | 3020 | 3820 | 4020 |

| Depth | 2970 | 2970 | 2970 | 2970 | 2970 |

| Height | 1610 | 1610 | 1610 | 1610 | 1610 |

| Weight | 13000 | 15000 | 17000 | 22000 | 24000 |

| Power | 15 | 15 | 25 | 25 | 25 |

| Speed | 0-20 | 0-20 | 0-20 | 0-20 | 0-20 |

| Minumum Pressure | 4 | 4 | 4 | 4 | 4 |

Description

MecTitan is a high-end product that does not accept compromises. The various components are designed to ensure a long service life. Every solution has been adopted that can improve leather quality and yield, while reducing maintenance and running costs.

To continue with our high customization philosophy based on the need of our customers, we offer various working widths, from1800 mm to 3400.

In turn, the number of heads may also vary. In any case, that the palissone is 2, 3 or 4 heads, it will always be supplied with two flying masses to maintain high skin quality.

These flying masses are moved by an eccentric and flywheel system, driven by electric motors. The two flying masses are in turn synchronized with pulleys and toothed belts.

Carpet handling is carried out with electric motor and inverter. Speed control can be changed and displayed by touch screen.

The structure and welding works are extremely reinforced. All metal parts, including heads and swinging masses, are made of heat-treated steel.

The connecting rods that give movement to the staking masses are a single element, consisting of a single fusion. This ensures greater resistance to mechanical stress, ensuring a lifetime of up to 50% over traditional systems.

The machine is equipped with air bubble shock absorbers, which, combined with soundproof carters, allow to limit the staking noise.

The last head of the staking machine has a mixed arrangement of the pins, half are square, half pin against pin. This solution eliminates any mark on the leather.

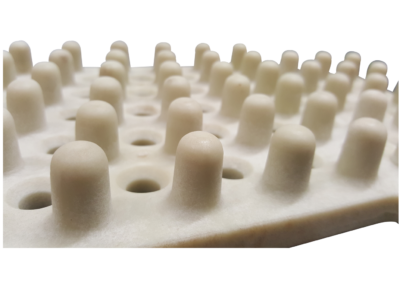

PIN PLATES

The plates in FRP (Fiber Reinforced Polimers), mean a significant reduction of the marks on the skin and a lower maintenance cost, while guaranteeing a very long working life.

This material is famous for its extreme resistance to abrasion and chemical aggression. These features ensure a useful life equivalent to metal plates.

The plasticity of this material further reduces the noise produced by the process and increases the quality of the staking.

In case of specific request by the customer, however, we provide aluminum plates or mixed compositions in FRP and metal.

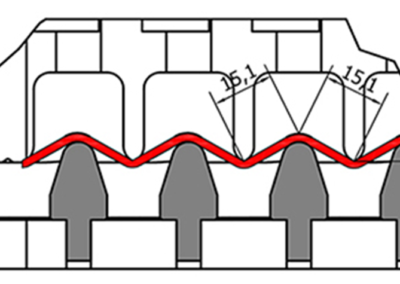

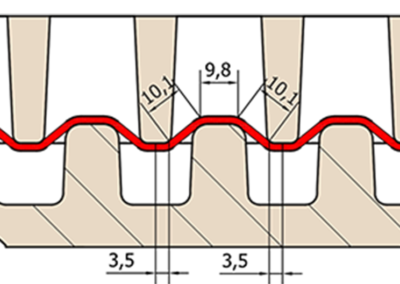

The very shape of the pins implies an improvement in the quality of the staking.

These, being wider, involve a larger area of leather. With the same work surface and working pressure, the leathers are processed more effectively, resulting in a smoother feel and gaining a larger surface.

Standard staking surface 15.1 + 15.1 = 30.2mm

Mec Titan staking surface: 3,5+10,1+9,8+10,1+3,5=37mm

By rationalizing the hydraulic system, it was possible to reduce the amount of oil needed to adjust the staking heads. While a regular staking machine needs 40 liters of hydraulic oil, Mec Titan uses just 5, resulting in considerable savings in running and environmental costs.